Aluminum Foundry is trusted for manufacturers in aluminum casting solutions

Wiki Article

The Duty of Aluminum Foundry in Enhancing Production Performance Across Diverse Sectors

Aluminum shops serve an essential feature in modern manufacturing by boosting production performance across different sectors. They harness progressed strategies and lasting practices to decrease and optimize operations waste. The effect of Aluminum encompasses industries such as vehicle, aerospace, and construction, where its one-of-a-kind residential or commercial properties improve efficiency. However, the challenges faced by these factories can shape their future. Recognizing these dynamics exposes an intricate landscape of innovation and adaptationThe Relevance of Aluminum in Modern Manufacturing

The adaptability of Aluminum allows a vast array of fabrication strategies, consisting of machining, extrusion, and casting. Its recyclability even more emphasizes its value, as recycled Aluminum requires substantially less power to create than brand-new Aluminum, aligning with contemporary ecological goals. As industries remain to evolve, Aluminum's one-of-a-kind attributes and versatility assure it stays an important material for driving advancement and performance in producing processes. Its payments extend beyond capability, supporting financial development and sustainability efforts around the world.

Secret Procedures in Aluminum Foundries

In Aluminum foundries, numerous vital processes are essential for accomplishing high manufacturing efficiency. Melting and alloying strategies, together with molding and spreading approaches, play a vital function fit the final item. In addition, executing strict quality control measures assurances that the result fulfills sector requirements.Thawing and Alloying Techniques

Melting and alloying are essential processes in Aluminum foundries, their performance greatly affects general manufacturing top quality and expense. The melting procedure normally entails making use of electric furnaces or gas-fired systems, which permit precise temperature control. This assures that Aluminum reaches its excellent melting point, reducing energy intake. Alloying, on the other hand, requires the enhancement of details components to attain wanted product residential or commercial properties, such as strength and corrosion resistance. Methods such as pre-alloying and in-situ alloying are commonly used to enhance uniformity and minimize waste. Mindful monitoring during both melting and alloying stages is essential, as it directly influences the material features and assurances conformity with market standards, inevitably resulting in improved manufacturing performance across various markets.Molding and Casting Techniques

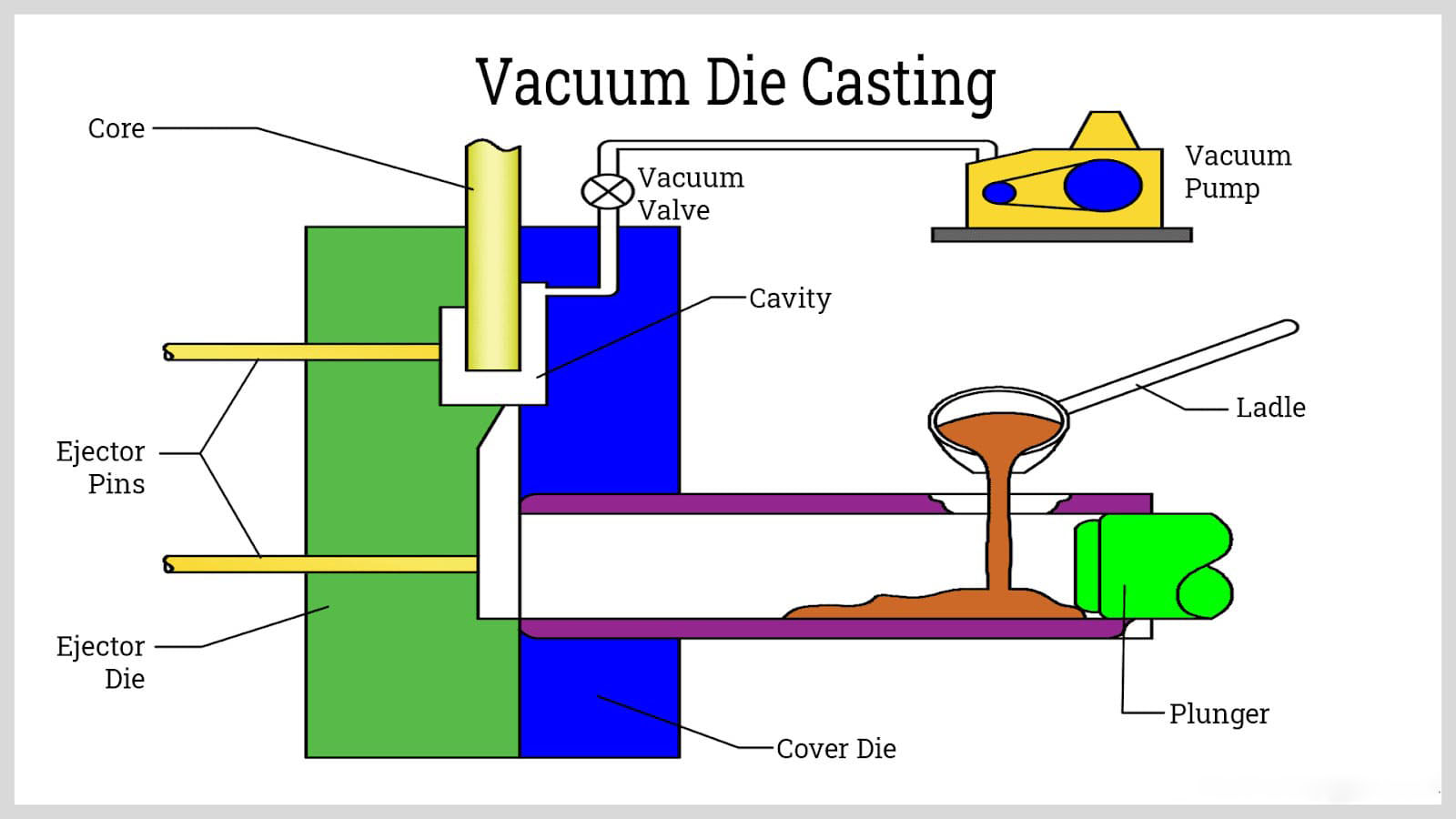

A variety of molding and spreading techniques are vital to the performance and top quality of Aluminum factories. Among these approaches, sand casting, pass away casting, and permanent mold and mildew casting stick out due to their one-of-a-kind benefits. Sand casting supplies versatility for complex forms and is cost-effective for reduced production quantities. Die casting, understood for its precision and repeatability, is ideal for high-volume manufacturing, providing exceptional surface finishes and dimensional accuracy. Irreversible mold spreading combines the benefits of both sand and pass away casting, enabling for far better mechanical properties and decreased product waste. Each method serves details applications across varied sectors, allowing Aluminum shops to optimize manufacturing procedures, decrease lead times, and meet varying consumer needs effectively.Top Quality Control Measures

Assuring top quality Aluminum items needs strenuous quality control procedures at every phase of the Foundry procedure. These measures begin with the choice of basic materials, where comprehensive screening for contaminations and make-up is important. Inspections throughout the molding and casting phases keep track of dimensions and surface quality to prevent defects once materials are approved. Advanced techniques, such as non-destructive screening, are used to detect internal flaws that might endanger item stability. Furthermore, process control systems continuously monitor temperature level and alloy composition to keep uniformity. Final evaluations, including mechanical residential property screening, verify that the products fulfill market requirements. By applying these rigid high quality control protocols, Aluminum foundries improve production efficiency and ensure the dependability of their products throughout varied industries.Developments Driving Manufacturing Effectiveness

Developments in Aluminum foundries are changing production efficiency via sophisticated spreading methods and the integration of automation and robotics. These growths not only streamline procedures but additionally enhance accuracy and decrease waste. In addition, sustainable product developments are adding to more eco-friendly techniques within the market.Advanced Spreading Techniques

Various innovative casting strategies are transforming the Aluminum Foundry market, substantially improving manufacturing effectiveness. Approaches such as die casting, sand casting, and financial investment casting have actually evolved, enabling for raised precision and minimized waste. Technologies like computer-aided design (CAD) and simulation software program enable factories to maximize mold and mildew design and forecast possible issues before manufacturing, reducing pricey errors - Aluminum Foundry. Furthermore, making use of alloy development methods improves product residential properties, resulting in items that fulfill stringent performance requirements. Strategies such as rapid prototyping and 3D printing are likewise getting grip, facilitating faster turn-around times for complicated geometries. These advancements not only streamline production processes but also add to sustainability initiatives by reducing energy intake and improving material usage in the Aluminum casting industry

Automation and Robotics Integration

The assimilation of automation and robotics in the Aluminum Foundry sector is revolutionizing production performance. By utilizing advanced robot systems for jobs such as molding, putting, and completing, foundries are markedly lowering labor expenses and reducing human error. Automated procedures improve production lines, permitting faster turnaround times and consistent top quality in produced components. In addition, the application of real-time monitoring systems enables drivers to track performance metrics and maximize workflows proactively. Robotics additionally improves safety by taking control of dangerous jobs, consequently reducing workplace crashes. As the innovation proceeds to develop, the Aluminum Foundry sector is poised to leverage these innovations additionally, guaranteeing competition and responsiveness in a progressively requiring market.

Sustainable Material Innovations

As the Aluminum Foundry industry seeks to enhance production effectiveness, sustainable material technologies are emerging as a crucial element. These technologies consist of the advancement of environmentally friendly alloys and using recycled Aluminum, considerably lowering the ecological impact of production procedures. Advanced strategies, such as additive manufacturing and eco-friendly casting methods, allow shops to decrease waste while improving material homes. In addition, the assimilation of bio-based binders and coatings results in much healthier functioning environments and lowers emissions. The adoption of life cycle evaluation devices more help shops in identifying sustainability opportunities, aligning with worldwide patterns toward accountable manufacturing. These developments not only enhance production efficiency but also place the Aluminum Foundry field as a leader in lasting industrial methods.Ecological Sustainability in Aluminum Casting

While Aluminum casting has long been a staple in production, its ecological influence has prompted a change in the direction of more lasting practices. Several shops are now adopting environment-friendly methods to lessen waste and energy intake. By making use of recycled Aluminum, factories significantly lower the demand for virgin products, thus conserving all-natural resources and lowering greenhouse gas exhausts.Advancements such as sophisticated melting innovations and boosted heating system designs in addition improve power effectiveness. Implementing closed-loop systems enables for the recycling of by-products and scraps, lessening landfill payments. Additionally, using water-based coatings and eco-friendly materials in find out here the spreading process minimizes harmful discharges and ecological toxins.

As markets significantly prioritize sustainability, the Aluminum spreading field is straightening with these worths, showing that economic growth and ecological duty can exist side-by-side. This commitment to lasting practices not only profits the setting however also settings Aluminum shops as leaders in responsible manufacturing.

Applications of Aluminum Parts in Different Industries

Aluminum parts are increasingly used throughout numerous sectors due to their distinct residential or commercial properties, which include light-weight stamina, deterioration resistance, and superb thermal conductivity. In the automotive industry, Aluminum is necessary for generating lighter lorries, contributing to improved gas efficiency and reduced emissions. The aerospace industry leverages Aluminum alloys for aircraft parts, taking advantage of their high strength-to-weight ratio, which enhances performance and safety.In construction, Aluminum is favored for home windows, doors, and roofing due to its sturdiness and visual appeal. The electric field employs Aluminum in high-voltage line and elements, benefiting from its conductivity and resistance to corrosion. Additionally, the consumer goods market uses Aluminum in product packaging and family products, promoting sustainability through recyclability (Aluminum Foundry). On the whole, Aluminum parts play a crucial role ahead of time technical innovations and operational performances throughout diverse markets, highlighting their value in modern manufacturing and design

Obstacles Encountered by Aluminum Foundries

Countless obstacles challenge Aluminum factories, affecting their efficiency and performance. One considerable problem is the volatility of resources prices, which can rise and fall unexpectedly, affecting functional costs and profit margins. In addition, shops commonly grapple with rigid environmental guidelines, requiring costly investments in lasting methods and waste monitoring systems. Labor scarcities existing an additional hurdle, as the competent workforce required for specialized processes comes to be increasingly limited, resulting in possible delays and high quality control issues.Technological combination poses difficulties; shops have to continually adjust to improvements in automation and digital tools to stay affordable. Inefficiencies in production procedures, such as poor melting and casting techniques, can likewise impede output. Lastly, the need for customized services across different sectors pressures shops to stabilize flexibility with efficiency, complicating production routines. Together, these challenges develop an intricate landscape that Aluminum shops have to browse to boost their general effectiveness.

Future Patterns in Aluminum Foundry Technology

As the Aluminum Foundry market advances, emerging modern technologies are established to reinvent manufacturing processes and improve performance. Innovations in automation, such as robotics and synthetic intelligence, are expected to improve procedures, decrease labor prices, and improve accuracy. Furthermore, improvements in 3D printing modern technology will certainly enable the fast prototyping of intricate Aluminum components, lowering preparations and product waste.Additionally, the integration of IoT (Web of Points) will certainly enable real-time tracking of manufacturing procedures, enabling predictive maintenance and decreasing downtime. Sustainability will likewise play a crucial role, with a raising emphasis on recycling and power efficiency in Foundry operations.

Often Asked Inquiries

What Are the Costs Connected With Aluminum Foundry Manufacturing?

The costs connected with Aluminum Foundry manufacturing consist of basic material expenses, labor expenses, power intake, maintenance of equipment, and overhead. These variables jointly influence the overall monetary feasibility and performance of the Foundry operations.How Do Foundries Make Sure Quality Assurance in Aluminum Spreading?

Shops guarantee high quality control in Aluminum spreading via strenuous screening methods, consisting of product evaluation, dimensional evaluations, and process tracking. Executing standardized procedures and using sophisticated innovations assists preserve consistency and satisfy industry specs throughout production.What Safety Steps Are Executed in Aluminum Foundries?

Security steps in Aluminum foundries consist of individual safety devices, appropriate ventilation systems, regular safety and security training, emergency situation methods, and devices maintenance. These practices aim to minimize risks, ensuring check my blog the well-being of employees and keeping operational performance.Just how Lengthy Does the Aluminum Casting Refine Typically Take?

The Aluminum spreading procedure usually takes a number of hours to several days, relying on variables like the complexity of the design, the size of the actors, and the particular techniques used by the Foundry.What Skills Are Required to Operate In an Aluminum Foundry?

To operate in an Aluminum Foundry, individuals require skills such as metallurgy knowledge, machining effectiveness, interest to detail, analytical capabilities, and teamwork. Safety and security awareness and technological experience in casting procedures are likewise vital for reliable operation.Its recyclability further highlights its importance, as recycled Aluminum calls for substantially less power to Continued produce than new Aluminum, straightening with contemporary ecological goals. A selection of molding and casting approaches are vital to the performance and high quality of Aluminum foundries. Advancements in Aluminum foundries are revolutionizing manufacturing efficiency through innovative casting methods and the assimilation of automation and robotics. Various sophisticated spreading methods are changing the Aluminum Foundry industry, significantly boosting manufacturing efficiency. Factories assure quality control in Aluminum spreading via strenuous testing procedures, consisting of material analysis, dimensional evaluations, and procedure surveillance.

Report this wiki page